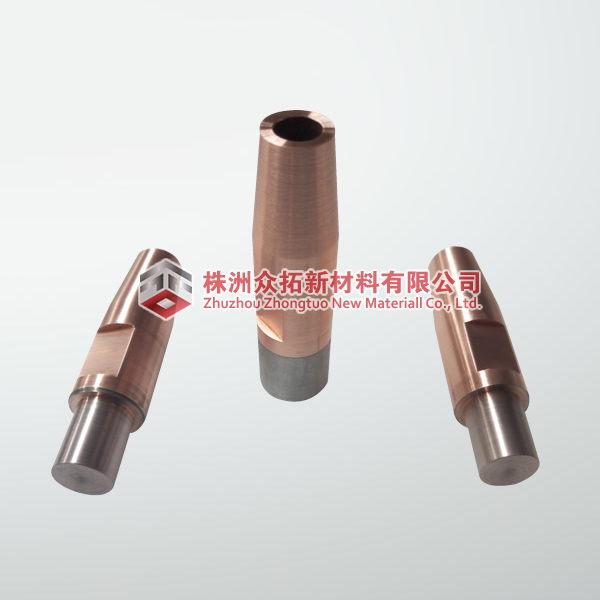

Molybdenum tips welding Electrode is used as an essential part of welding of high conductive metals like copper. It is also used for roller welding and upset welding purpose. Besides having high conductivity level, this type of electrode shaft exhibits good physical stability under high temperature. It contains BeCu and copper. Apart from its good machinability, this electrode shaft is preferred for its accurate composition, long working life, corrosion resistance capacity and fracture proof formation. We would like to introduce ourselves as a growth oriented manufacturer of excellent quality Molybdenum tips welding Electrode.

Features

High temperature proof formation

Precise design

Long working life

Good welding performance

More Key Points:

Shape : Strip

It is an Alloy

Grade : CuCr ,CuCrZr,WCu

Color : Copper red

Warranty : as per the contract

Surface Treatment : Polished

Technical Specification :

RWMA Group A

CuCr and CuCrZr

| Content (%wt.) | Density (g/cm3) | Conductivity (%IACS) | Hardness (HRB) | RWMA |

Cr: 0.6-1% | 8.9 | 70 | 85 | Class 2 |

Cr: 0.5-1.5%, Zr: 0.05-0.25%, Cu: balance | 8.9 | 80 | 80 | Class 2 |

Nickel Silicon Copper

| Composition | Density (g/cm3) | Conductivity (%IACS) | Hardness (HRB) | RWMA |

Si: 0.60-1.1% Ni: 2.4-3.4% Cu: balance | 8.83 | 40 | 90 | Class 3 |

CuCo2Be

| Content (%wt.) | Density (g/cm3) | Conductivity (%IACS) | Hardness (HRB) | RWMA |

Be: 0.40-0.70% Co: 2.40-2.70% Cu: balance | 8.83 | 45 | 95 | Class 3 |

RWMA Group B

Refractory Metal

Tungsten copper :

| Composition | Density (g/cm3) | Hardness (HRB) | Conductivity (%IACS) | RWMA |

W50Cu50 | 11.9 | 65 | 54 |

|

W55Cu45 | 12.5 | 70 | 49 | Class 10 |

W70Cu30 | 14.1 | 82 | 42 |

|

W75Cu25 | 14.5 | 90 | 38 | Class 11 |

W80Cu20 | 15.2 | 98 | 34 | Class 12 |

W85Cu15 | 15.9 | 240HB | 30 |

|

W90Cu10 | 16.75 | 260HB | 27 |

|

Tungsten

| Composite (%wt.) | Density (g/cm3) | Hardness (HRC) | Electrical Conductivity (%IACS) | Class | RWMA | Comparison |

W -99.95 | 19.3 | 36 | 30 | 13 | 13.743 | High temperature resistance |

W-Ce (CeO2:2%) | 19.2 |

|

|

|

| Low electric discharge power, fine arc-starting performance, excellent arc erosion resistance, longer service life |

W-La (La2O3: 1-2%) | 19.2 |

|

|

|

| Low electric discharge power, easy for machining |

Molybdenum

| Comparison (wt.%) | Density (g/cm3) | Hardness (HRB) | Electrical Conductivity (%IACS) | RWMA | Comparison |

Mo 99.95 | 10.2 | 90 HRB | 30 | 14.423 | Superior electrical and thermal conductivity |

TZM (Ti: 0.5%, Zr: 0.08%, C: 0.02%) | 10.17 |

|

|

| High thermal and creep resistance |

Mola (La2O3: 0.1 -1.8%) | 10.19 |

|

|

|

|