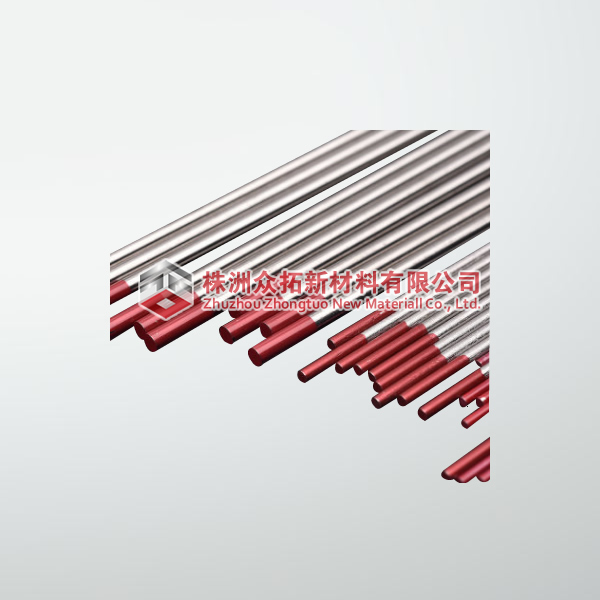

Pure Tungsten Electrode

Description

Pure tungsten electrode, also known as wolfram electrode, can be manufactured with black surface, polished surface or ground surface. It is normally marked with green. This kind of tungsten welding electrode is firstly used when welding argon arc. But under DC welding condition, the electrode can't prone to arc and may maintain unstable situation. In these circumstances, adding rare earth oxide can greatly improve the situation. Pure tungsten electrodes can work as welding electrode under ac condition or as resistance welding electrode.

Pure tungsten electrodes (AWS classification EWP) contain 99.50% tungsten and are typically less expensive than "alloyed" counterparts.

Performance

1. Pure tungsten electrode provides great arc stability for AC welding with balanced wave. It also provides good arc stability for AC sine wave welding, especially on aluminum, magnesium, their alloy and stainless steel.

2. This tungsten welding electrode has superior features of small steam pressure, low resistance, good electrical conductivity and small thermal expansion and high elastic modulus.

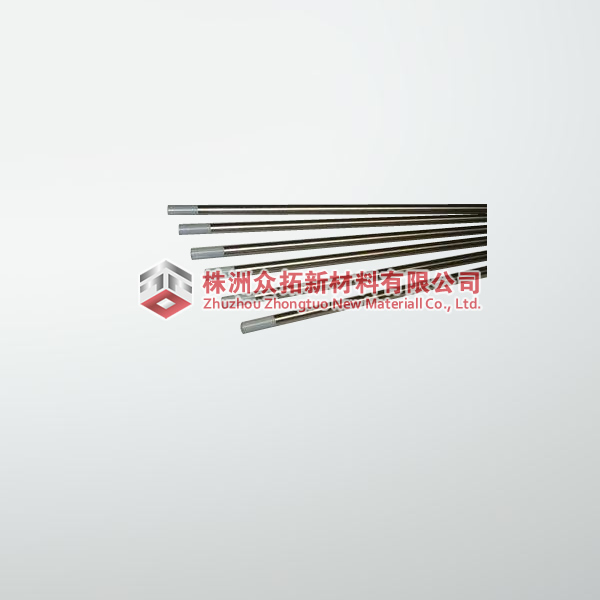

Technical Parameters of Pure Tungsten Electrode

| Diameter(mm) | Tolerance( mm ) | Length( mm ) |

Φ1.0-Φ2.4 | ±0.05 | 50~175 ±1 |

Φ3.0-Φ12.0 | ±0.1 |

Attention

When you choose TIG tungsten electrode, you should attach much importance on its type, diameter, quality, surface roughness and tip geometry.

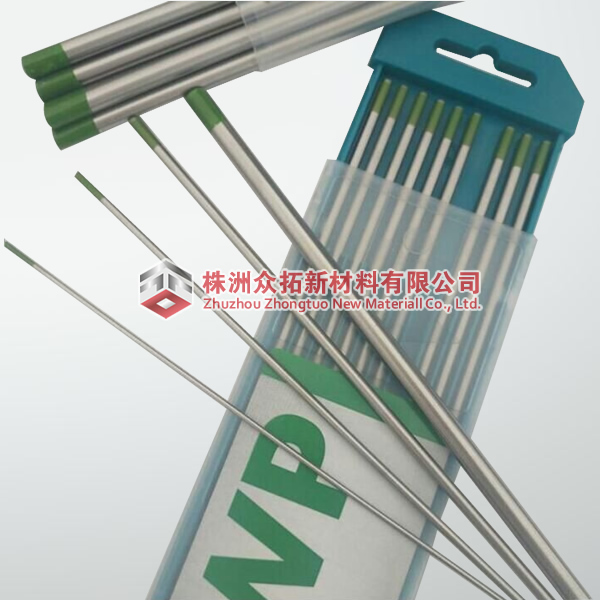

Package and Transportation

We normally pack ten pure tungsten electrodes in a plastic box with mark and several boxes in a plywood case by sending them via ocean or air.

Thoriated Tungsten Electrode

Description

2% thoriated tungsten electrode, which is also known as WT electrode, contains a minimum of 97.30% tungsten and 1.70 to 2.20% thorium. Featuring longevity and ease of use, they've become the most commonly used electrodes today.

Thorium plays an important role in increasing the electron emission qualities of thoriated tungsten electrode, which can improve arc starts and allow a higher current carrying capacity.

As thoriated tungsten electrode operates far below its melting temperature, there is considerably lower rate of consumption and less arc wandering for greater stability. It also features making less welding contamination than other electrodes.

To meet different customers' needs, we are able to provide various kinds of thoriated electrodes with different content of thorium.

Advantages of Thoriated Tungsten Electrode

1. Lower electronic functions

2. Higher crystallization temperature

3. Better conductivity

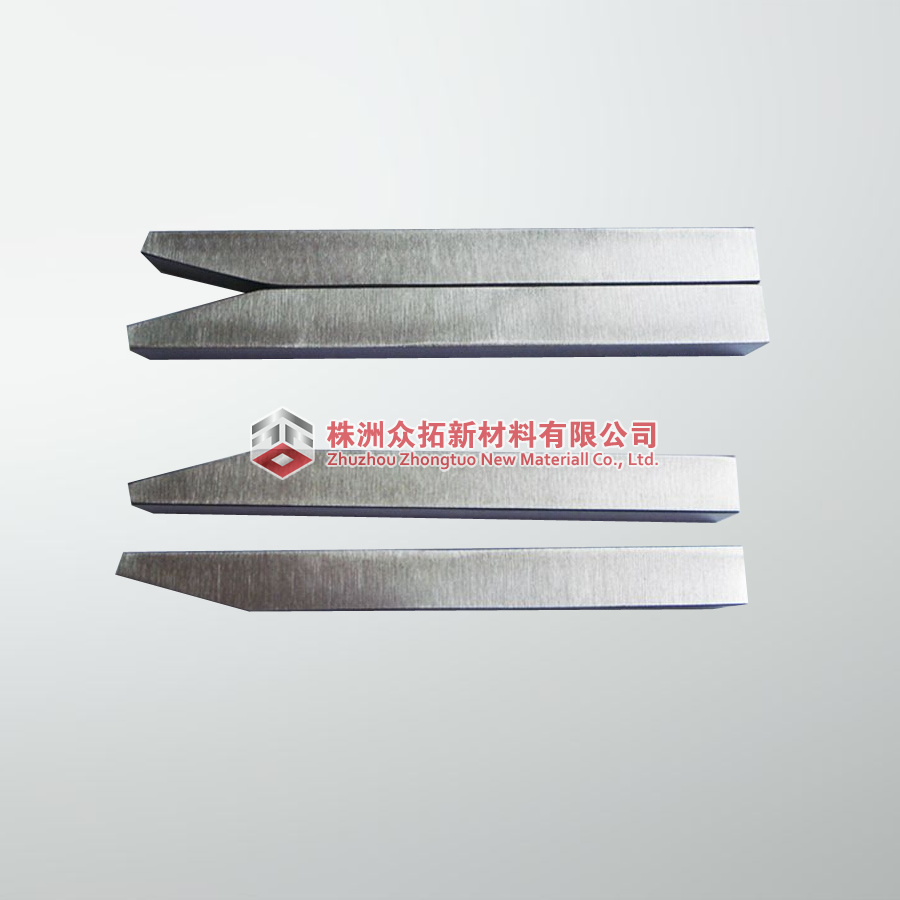

4. Superior mechanical cutting performance

Application

Unlike pure tungsten, these thoriated tungsten electrodes are suitable for specialty type AC welding (thin gauge aluminum or materials less than 060-in.), but they are exceptional for DC electrode negative or straight polarity on carbon and stainless steel, nickel and titanium applications.

In the process of production, thorium is evenly dispersed throughout thoriated tungsten electrode and such evenness makes it possible for the electrode to maintain a sharpened edge—the ideal electrode shape for welding thin steel.

Parameters of Thoriated Tungsten Electrode

| Type | Additives | Content | W% | Sing color |

WT10 | ThO2 | 0.90~1.20% | >98.4 | Yellow |

WT20 | ThO2 | 1.80~2.20% | >97.5 | Red |

WT30 | ThO2 | 2.80~3.20% | >96.5 | Purple |

WT40 | ThO2 | 3.80~4.20% | >95.6 | Orange |

Tolerances of this Thoriated Tungsten Electrode

| Diameter( mm ) | Tolerance (mm) | Length (mm) |

Φ0.30-Φ2.0 | ±0.05 | 50~175 ±1 |

Φ0.30-Φ2.0 | ±0.1 |

Attentions

1. Since thorium is radioactive, you must always follow our warnings and instructions.

2. Pay attention to the type, diameter, quality, roughness, and tip geometry of thoriated tungsten electrode.

Packaging and Transportation

We normally pack ten thoriated tungsten electrodes in a plastic box with mark and several boxes in a plywood case by sending them via ocean or air

Lanthanated Tungsten Electrode

Description

1.5% lanthanated tungsten electrode, which is also known as WL electrode, contains a minimum of 97.80% tungsten and 1.30 to 1.70% lanthanum, or lanthana. To optimize your welding capabilities, you can consider it as a best choice.

Lanthanated electrode works well on AC or DC electrode negative with a pointed end or they can be balled for use with AC sine wave power sources. The lanthanum is dispersed evenly throughout the entire length of the lanthanated tungsten electrode in the process of production. This lanthanated tungsten electrode also maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or the AC from squarewave power sources.

Compared to pure tungsten, the addition of 1.5% lanthana increases the maximum carrying capacity by approximately 50% for a given size electrode.

We can manufacture lanthanated tungsten electrodes with different content of lanthanum.

Features

Lanthanated tungsten electrode features excellent arc starting, low-burn-off rate, good arc stability and excellent re-ignition characteristics—many of the same advantages as ceriated electrodes. As 1.5% lanthanated tungsten electrode and 2% thoriated tungsten possess close resemblance, 2% thoriated, in some cases, can be replaced without having to make significant welding program changes.

Application

Unlike thoriated tungsten, these lanthanated tungsten electrodes are suitable for AC welding and, like ceriated electrodes, allow for the arc to be started and maintained at lower voltages.

Parameters of Lanthanated Tungsten Electrode

| Type | Additives | Content | w% | Sing Color |

WL10 | LaO2 | 0.80~1.20% | >98.4 | Black |

WL15 | LaO2 | 1.30~1.70% | >97.5 | Golden Yellow |

WL20 | LaO2 | 1.80~2.20% | >96.5 | Sky Blue |

Tolerances of this Lanthanated Tungsten Electrode

| Diameter (mm) | Tolerance (mm) | Length (mm) |

Φ1.0-Φ2.4 | ±0.05 | 50~175 ±1 |

Φ3.0-Φ12.0 | ±0.1 |

Packaging and Transportation

Generally, ten lanthanated tungsten electrodes are packed in a plastic box with mark and several boxes in a plywood case and are sent by ocean or air.

Cerium Tungsten Electrode

Description

2% cerium tungsten electrode, which is also known as WC electrode, contains a minimum of 97.30% tungsten and 1.80 to 2.20% cerium. It performs optimally in DC welding in the low current environment but can be used proficiently in AC or DC processes.

To meet different customers' needs, we are able to provide various kinds of wolfram cerium electrodes with different content of cerium.

Application

Cerium tungsten electrode has become popular in such applications as orbital tube and pipe manufacturing, thin sheet metal work or jobs where small and delicate parts are welded by virtue of its excellent arc starts at low amperages. Like thorium, this cerium tungsten electrode is most appropriate for welding carbon and stainless steels, nickel alloys and titanium, making it an ideal replacement for 2% thoriated electrodes.

Advantages of Cerium Tungsten Electrode

1. Non-radiation

2. Low melting rate

3. Long welding life

4. Good arc resistance

Features of Cerium Tungsten Electrode

Cerium tungsten is slightly different in electrical characteristics from thorium but most operators are not able to tell the difference. And it is recommended to use cerium tungsten electrodes at lower amperages. If in higher amperage situations, the oxides will migrate quickly to the heat at the tip, removing the oxide content and nullifying its process benefits.

Notes

Cerium tungsten electrode is not suitable for applications under high current condition, because under that condition the oxides will rapidly migrate to the heat zone, namely the top of the electrode welding point, which will damage the evenness of the oxides.

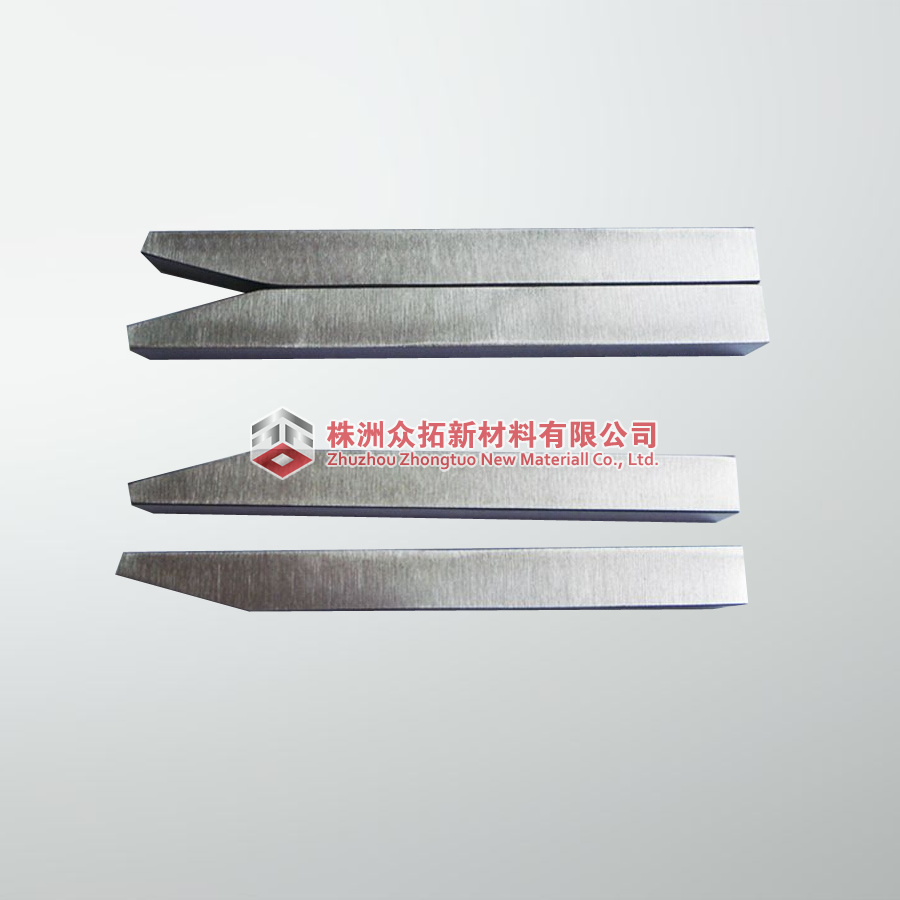

Essential Parts of Cerium Tungsten Electrode

| Type | Oxide Addition | Other Doping Content | Tungsten Content | Color-code Coating | |

Doping object | Doping % | ||||

WC20 | CeO2 | 1.8-2.2 | <0.20 | Balance | Gray |

Parameters of Cerium Tungsten Electrode

| Type | WCe10 | WCe15 | WCe20 | WCe30 | WCe40 |

As- finished | Rod | Wire | |||

Diameter Range(mm) | 1.0-10.0 | 0.8-0.2 | |||

Surface Condition | Black or Ground Polished | Black or Polished | |||

Tolerances of Cerium Tungsten Electrode

| Diameter ( mm ) | Tolerance( mm ) | Length( mm ) |

Φ0.30-Φ2.0 | ±0.05 | 50~175 ±1 |

Φ0.30-Φ2.0 | ±0.1 |

Packaging and Transportation

We normally pack ten cerium tungsten electrodes in a plastic box with mark and several boxes in a plywood case by sending them via ocean or air.